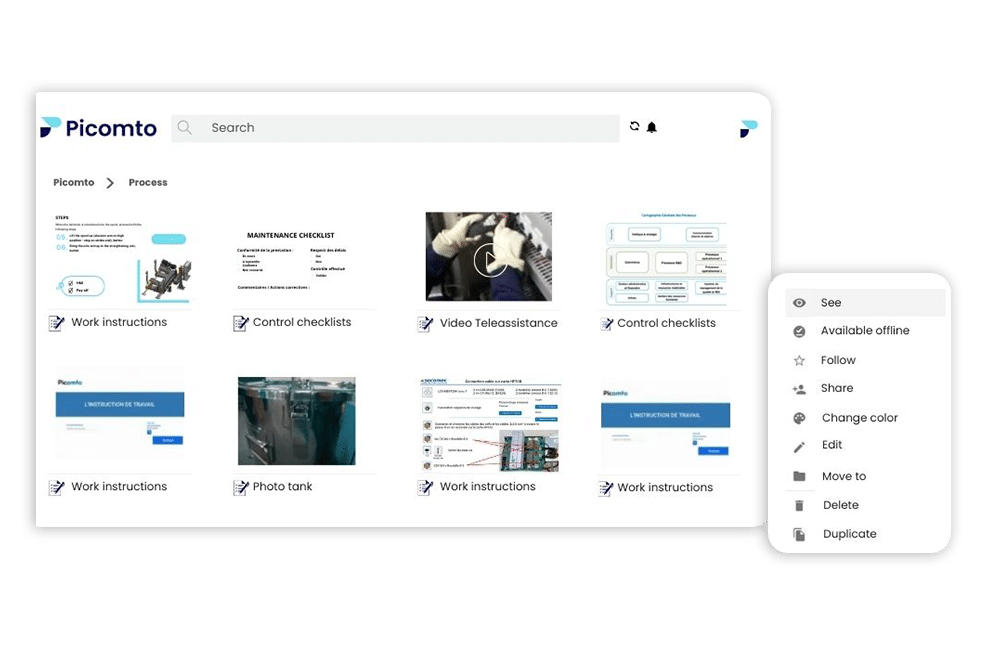

Documentary conciliation

Maintain constant alignment between your operating procedures and checklists.

Document reconciliation is a critical component in the chemical industry, ensuring the quality, regulatory compliance, and safety of manufactured products, materials, and personnel.

Traceability

Enhance the oversight of your operations and the connection between the control room and the field.

By optimizing the link between the control room and the field with Picomto, you can:

“Picomto participates in our Lean approach and allows us to question our methods and our processes.”

Alain Boutet

Process Methods Manager

efficiency during maintenance rounds

trips avoided each year

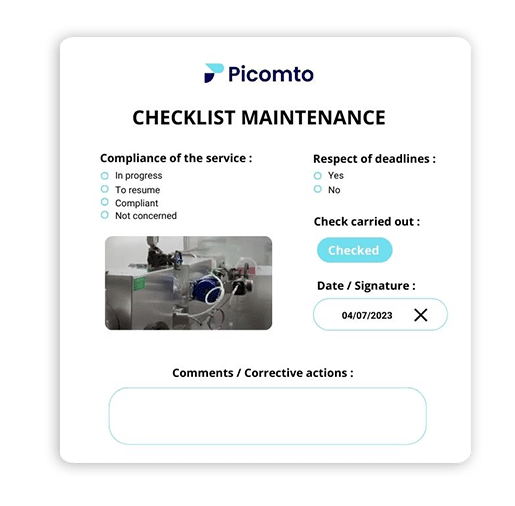

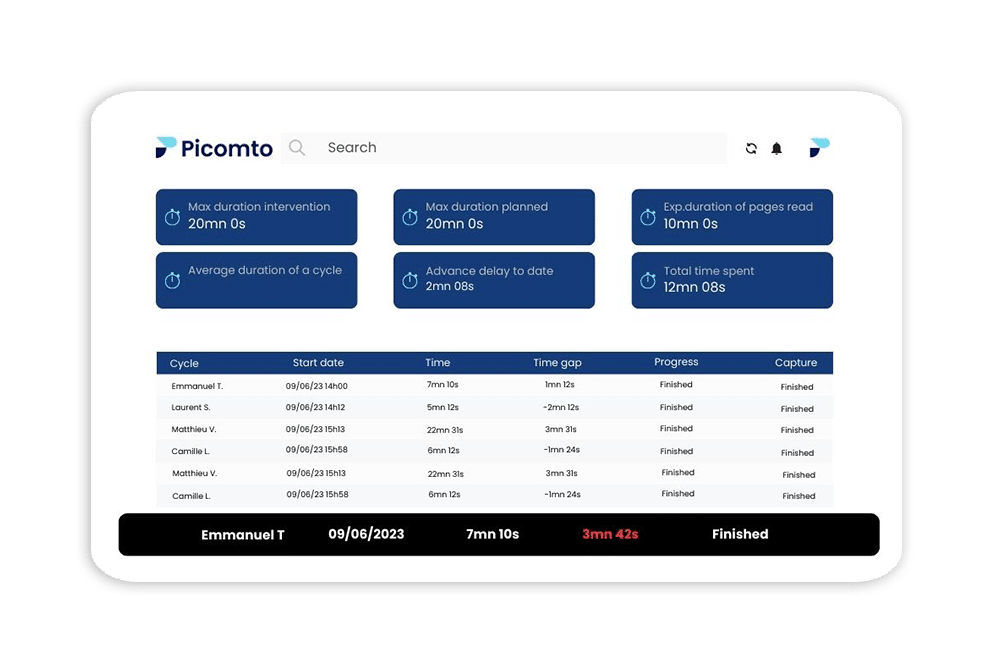

Real-time data

Don’t just react to deviations, anticipate them

Monitor outgoing productions and elements in real-time to prevent any process deviations. In the chemical industry, it’s crucial to minimize production variations and prevent the creation of defective products that cannot be sold. With Picomto, you can identify potential issues and reduce production waste. Similarly, Picomto is an indispensable tool for enhancing the safety of your industrial sites.

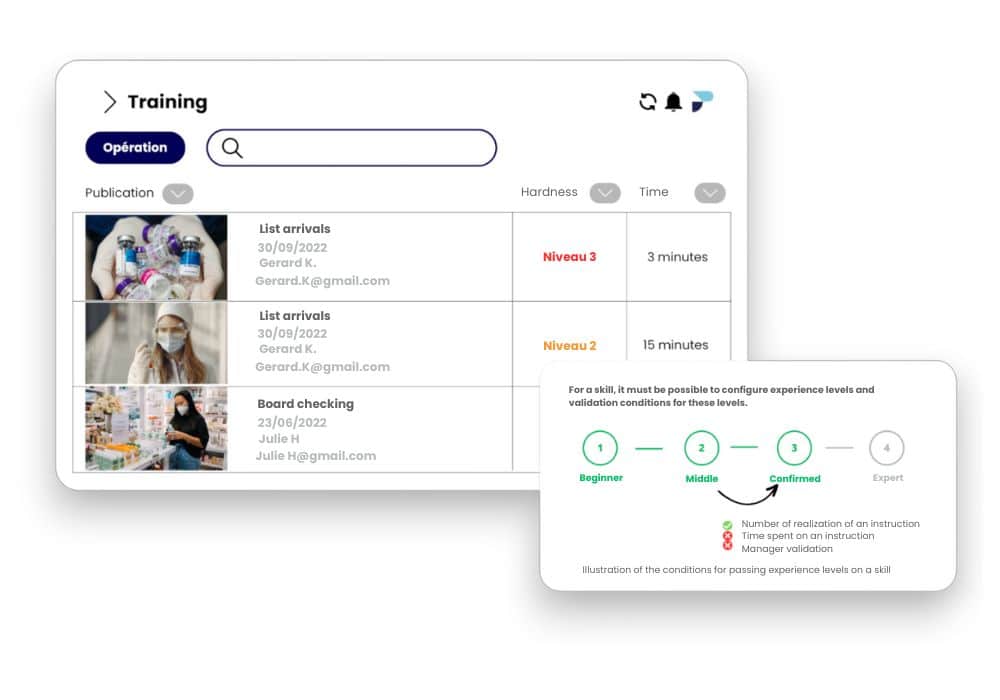

Operators’ training

Preserve the expertise of your experts

Simplify the transfer of knowledge from experts to operators and enable their rapid, independent training by digitizing operational expertise.