Maintenance

Answer your daily maintenance issues

+ 50 production lines equipped Picomto

1. You must manage your human and material resources

Thanks to Picomto, you can broadcast your orders in 1 click on the factory computers and tablets or even follow your factory in real time with Powerbi.

2. You must reduce stoppages

Thanks to Picomto, you can access automated dashboards in real time and thus identify the causes of drifts and reduce human errors.

3. You must guide your operators remotely

Thanks to Picomto, you can create a training course on each line of your production and thus disseminate your instructions everywhere, all the time, everyone.

The typical day of a connected maintenance technician with Picomto

Trigger of an intervention order

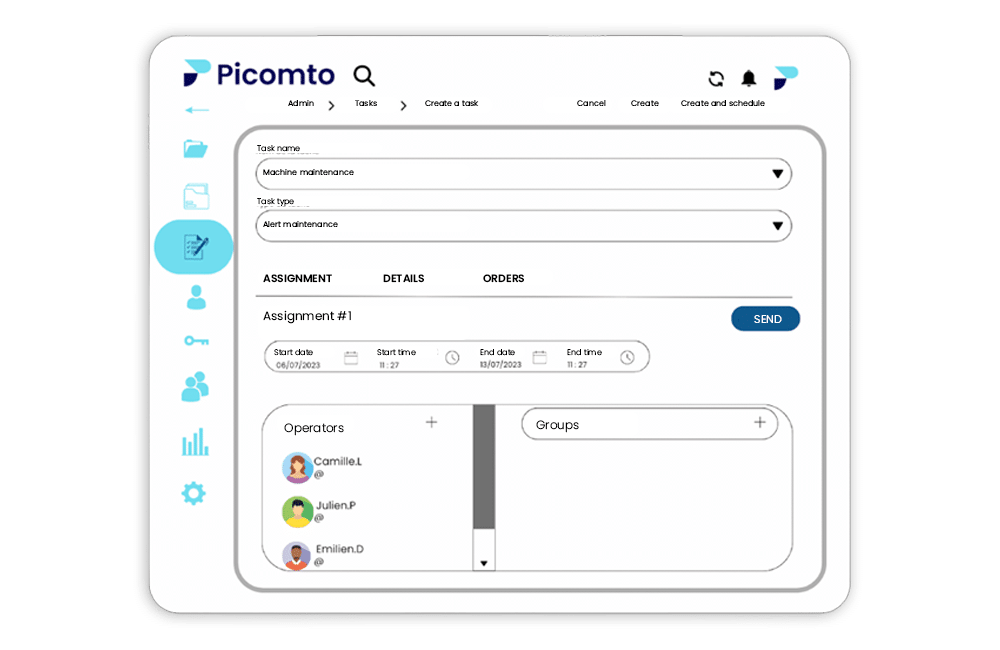

In Picomto you can even create your intervention orders. We have an integrated tool that allows you to create maintenance tasks and associate all technical documentation and checklists to fill in one click.

If you have an existing GMAO we can recover the intervention orders directly in it. Thanks to our REST API, we can also recover stocks of consumables, open or close an intervention order, make consumption of parts or consumable in the GMAO or go up time.

Connect your automata or artificial intelligence platforms for monitoring your picomto processes. To monitor an event, by the simple call of an URL you can create the maintenance task to solve the problem in Picomto. You can also automatically affect the right teams and hardware resources. Your technicians are connected in real time to machines and it is they who define their intervention needs.

Easily connect the machines and men. Automatically trigger your orders after x operating hours or x parts manufactured or depending on thresholds reached on production values.

Organize your maintenance operations

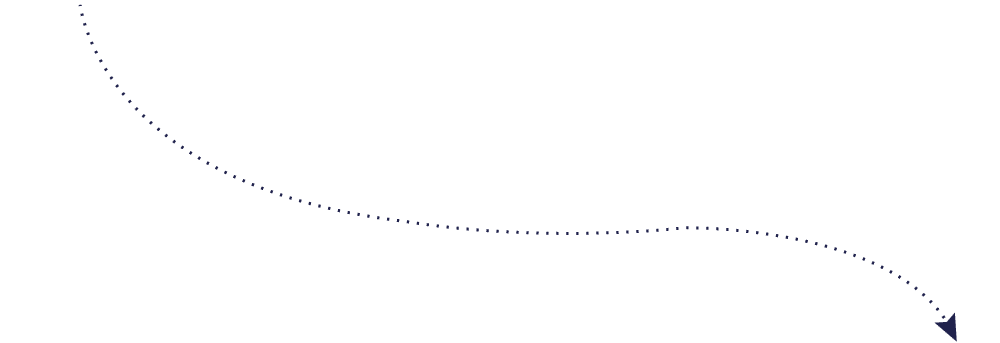

In Picomto you have a graphic tool to plan your orders. Thanks to you plan your orders in 1 second in a modern way and visualize the use of your teams in a clear dashboard.

Change planning and assignments as easily as a “”click/drop””. You know permanently or you are.

Visualize the team load or build yourself the best dashboard adapted to your activity.

Visualize the machines at a glance or those that will be.

Unroll your curative and preventive maintenance operations and automatically plan the predictive maintenance

Distribute your orders in 1 click on all computers and tablets from the factory. Use augmented reality with realwear or mixed reality with Hololens 2 to assist your operators even better. You have nothing to do! It is Picomto that adapts your orders and the associated technical data.

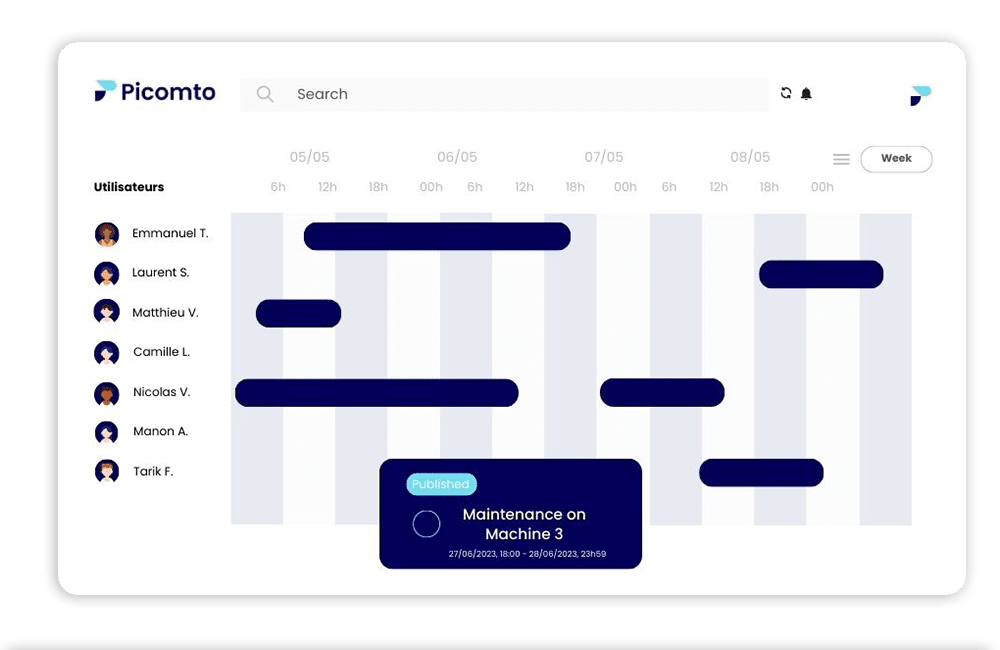

In 1 click operators see the charge of day or week and can start their activities.

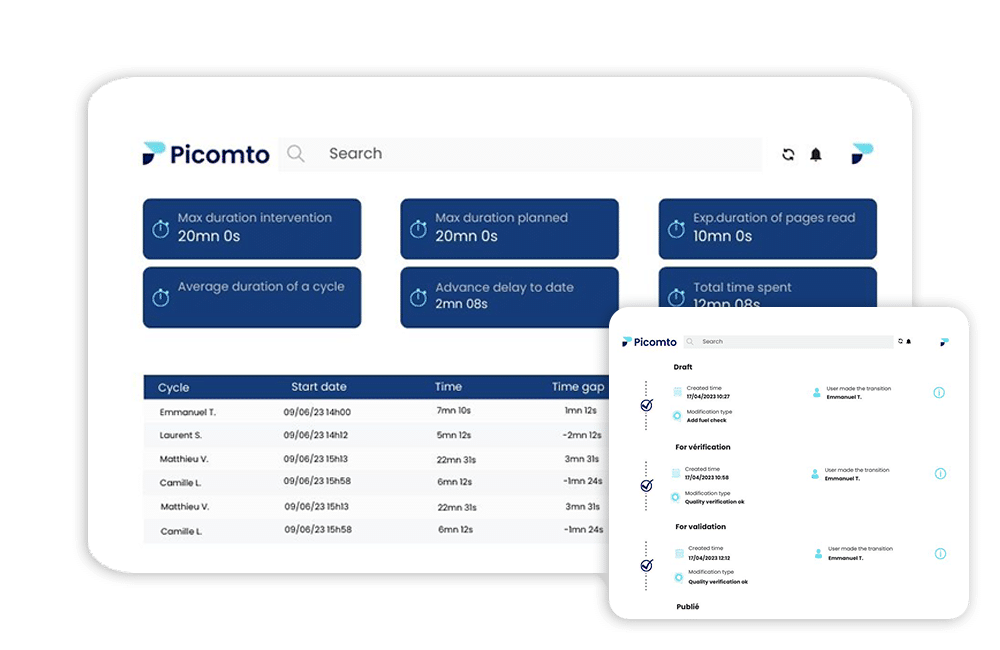

Nothing to do! Picomto points to time by range automatically as the technicians advanced. You will follow times in real time by range operation, by sub-operation and for each of your orders.

Available work instructions, operating modes and real -time procedures, intelligent and versioned, available to your operators. Your operators will follow an established and repeatable process, which will form and assist them.

Give access to digital checklists or integrate them into your work instructions. By giving your operators the possibility of entering the data over the water, you delete the risk of forgetting important information and prevent the checklists to be filled mechanically at the end of the Order.

Transform your work instructions by assisting virtual. Picomto allows you to digitize the experience of your technicians to assist the whole factory in real time. Workflow, decisions tree, color change of graphic elements according to the situation encountered, automatic alert, calculations, redirection rule, color change on threshold … thanks to artificial intelligence and image comparison you can help operators in their quality control over production.

Picomto has its own remote -year and telepresence module. In closed circuit, with our own encryption keys, without access to any external service you can contact an expert or management to be assisted or validate remote operations. The implementation in Picomto makes it possible to integrate distant people into the production workflows at the crucial stages. You can film your sensitive processes or your factory without being afraid that your data flows will be intercepted or seen by your competitors.

Picomto is one of the only solutions where you can work simultaneously on the same task side by side or remotely. Your technicians and operators are synchronized in real time and everyone sees what others do. You can create intelligent workflows and condition access to the actions of some depending on the proper realization of other stages of others. Each operator sees the multimedia content captured by others and all the values entered in real time.

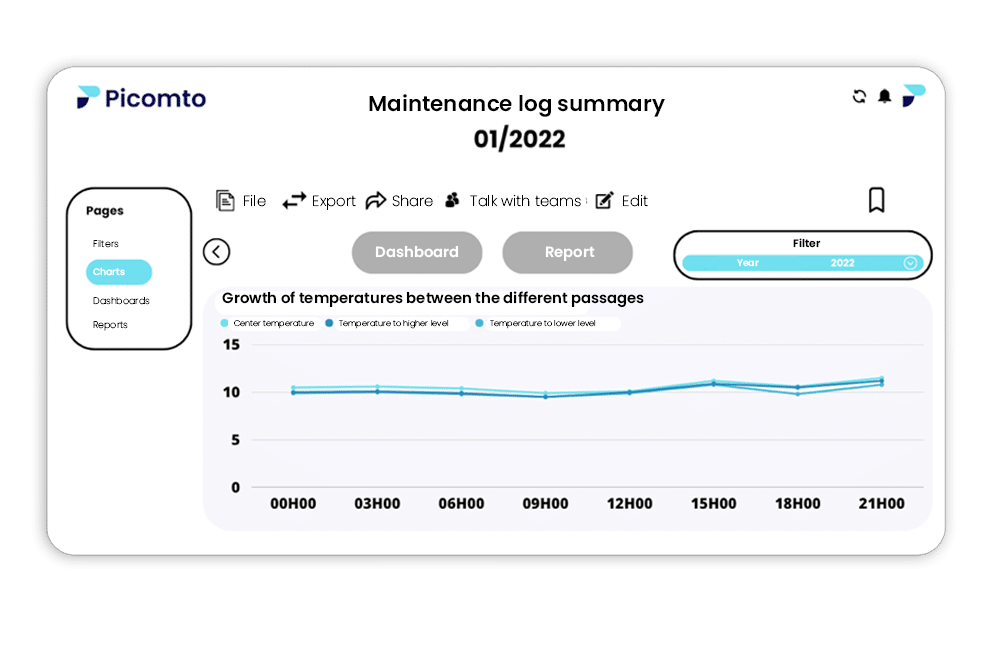

Follow production effectively with real -time dashboards, the Picomto back office or with tools like Powerbi. Share key information with your customers, use data to make reports or feed your continuous improvement processes.

Close your orders with a click

Picomto manages the resumption of cycles. You can work together in synchronous or asynchronous. When all the mandatory steps and the required fields are filled you can click your intervention orders in 1 click.

Picomto is responsible for closing your intervention orders in the GMAO without doing anything. Thanks to our API you also go up the intervention times, the resources that have intervened, the intervention reports and everything you want from the values entered during the intervention.

In the blink of an eye you know where you are, your orders not started, the current orders and the ended orders appear in the synthetic form easily.

Value your data in reports and dashboards

Picomto allows you to create personalized report templates. Use them to automatically generate your intervention reports. Store these reports in Picomto, send them automatically by email you want or go back to the third -party applications of your software environment.

Use the Power Bi connector to build and follow your dashboards in real time. Picomto can also build HTML dashboards for you to display in the factory or on management smartphones.

Follow the key constants of your machines, immediately view the slightest drift and predict the breakdowns. Automatically program interventions before your equipment broke out

Use all the data collected in Picomto, Power Bi but also in all the third -party solutions around you. Fund your continuous improvement processes.

Incorporate the telemaintin into your habits

Thanks to the power of digital instructions, help your technicians use or keep your products. Update, in real time, the instructions you make available to them. Avoid breakage linked to poor uses.

Stay connected to your technicians, add checklists to your user or maintenance instructions to supply your continuous improvement processes. Easily detect the possibilities of improving your equipment

Reduce your carbon impact everything decreasing your intervention times and the downtime of your equipment. Connect your technicians in real time by providing them with an efficient and secure telemaintin tool. Master the encryption of data flows and rest efficient in remote preventive and curative maintenance.

Expand your offer through real -time assistance of your customers for the use and maintenance of your products. Offer an evolutionary documentary base and effective maintenance options to reduce downtime and optimize the TRS of equipment.

Find out how Butachimie digitized its production operations

Butachimie is a Seveso site in Alsace, France, manufacturing basic chemicals for industry. With Picomto, it wanted to go one step further in enhancing operator safety:

- Reduce inspection errors

- Improve exchanges between employees in real time

- Complete traceability

efficiency on maintenance rounds

on time creation and provision of operating methods