Answer your daily production challenges

+ 50 production lines equipped Picomto

1. You must manage your human and material resources

Thanks to Picomto, you can broadcast your orders in 1 click on the factory computers and tablets or even follow your factory in real time with Powerbi.

2. You must reduce stoppages and eradicate deviations

Thanks to Picomto, you can access automated dashboards in real time and thus identify the causes of drifts and reduce human errors.

3. You must store the know-how of outgoing operators

Thanks to Picomto, you can create a training course on each line of your production and thus disseminate your instructions everywhere, all the time, everyone.

The digital training course from beginner to business expert with picomto

Newcomer reception

Thanks to Picomto the operator has access to reception procedures such as security procedures, reception at the post, reception in the sector from the first day. He is formed independently and the expert who takes care of his training takes place only at the key steps or to validate the training.

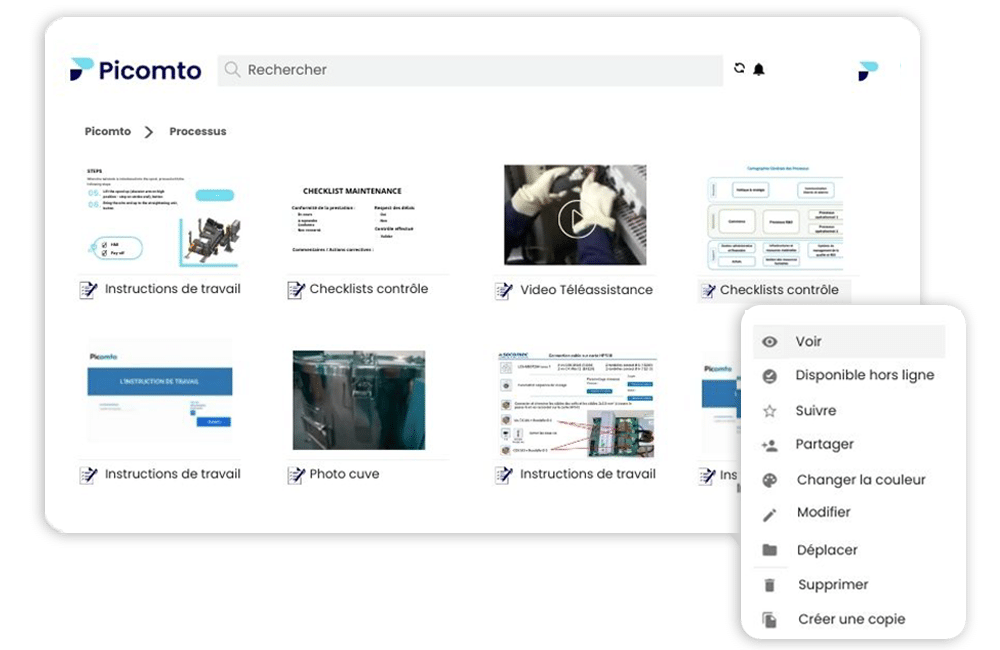

The operator has access to what he needs and only what he needs. Picomto’s secure sharing provides access to all of the documentation with one click.

Thanks to the power of the Picomto editor, you create routes mixing the photo, the video, the shapes and any other media. The trained person more easily includes each step without the need to be duplicate.

Each instruction has a single QR code which always points to the latest validated version of a document. The operator is physically guided from one training stage to another by the system and itself scans the training module when it reaches the area.

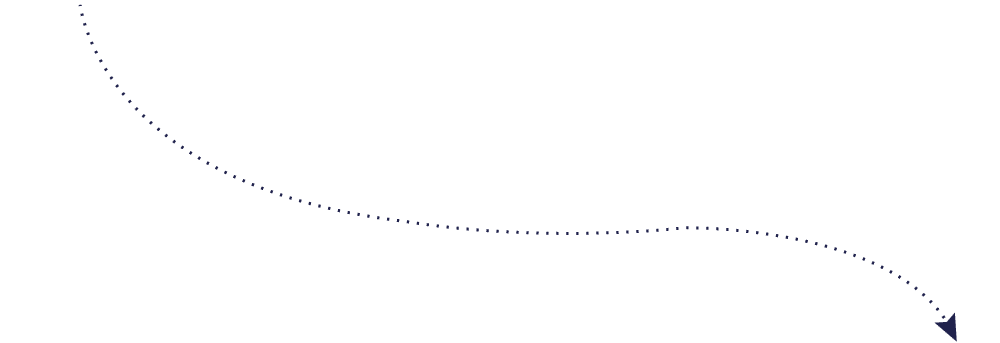

Reading and understanding

This corresponds to a first reading of a guide before you can use it. Restrictions prevent users from carrying out tasks before having read and understood the linked guides. It is possible to define which type of document should be reread before use.

When re-reading a guide, a user will run through all the pages of the guide and then complete a unique questionnaire to confirm their understanding.

Before the publication of a new version of a guide, it is possible to give users for a while to take it into account. This revision is then in status “”Read and Understanding”” during the time defined and the previous version remains that in force in the workshop.

During the assignment of users, a task, ordering or manager are informed that assigned operators or technician have not read all the necessary guides.

Each manager can visualize the reading statutes of the guides their teams in back office. It can act instantly with people late to avoid problems.

Beginners’ business training

With the skills management module, operators and technicians do not pass a real business career. Thanks to Picomto, you define the conditions required to be considered as a beginner. For example, the route can include observation, supervised and autonomy production phases. You easily define each training course and thanks to the simultaneous work in Picomto, we verify that each tutor and tutoré have done each stage of the route.

For each training, the process can be fully automatic or with validation of the team leader. Each team leader has a complete vision of the training state of his teams and can validate or launch additional training.

You no longer have to manage two systems in parallel. Replace the training modules that cost you to maintain and create with your factory work instructions. Your operators are formed from the first day from the documents they will use in the factory.

With Picomto you create the training courses in a few minutes. You define the conditions to be fulfilled to be considered as a beginner trained and Picomto automatically checks the right damage to each of the steps. For example, you can define how many times the operator to train must follow an operating mode at the same time as an expert performs the task. Then we reverse the roles and it is the expert who looks. Finally, the operator alone performs the action and the team leader validates training. Thanks to the work simultaneously, Picomto am each of the steps and allows you to make sure that the operators have gone through each of them.

Picomto provided to the manager of visual monitoring dashboards that allow you to know at a glance or are each member of the team. The team leader can therefore act on the differences and ensure that he has the necessary and competent resources for the execution of the tasks to come.

Skills management

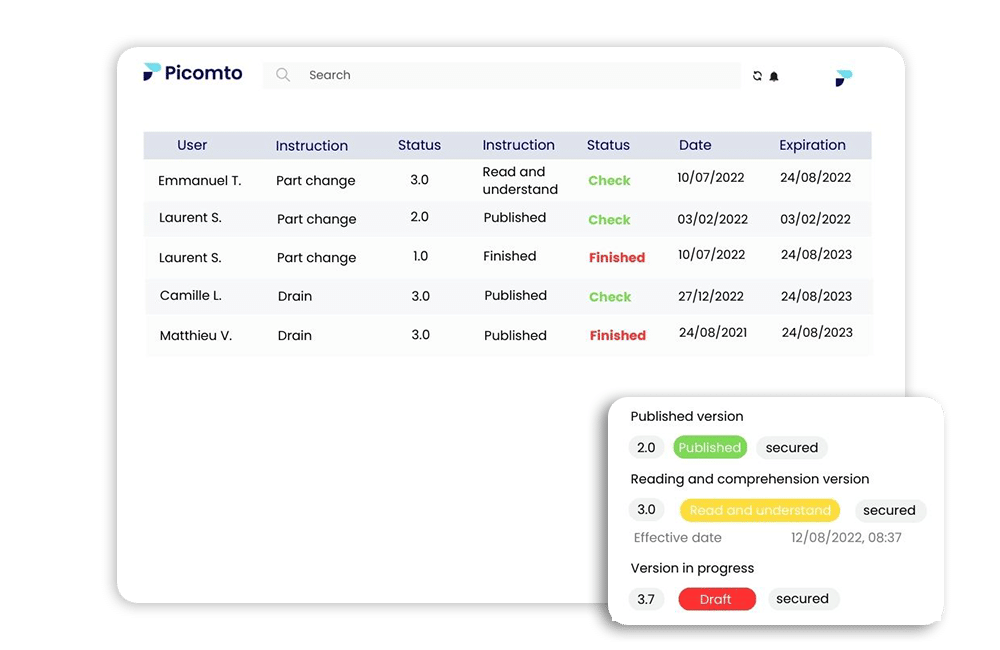

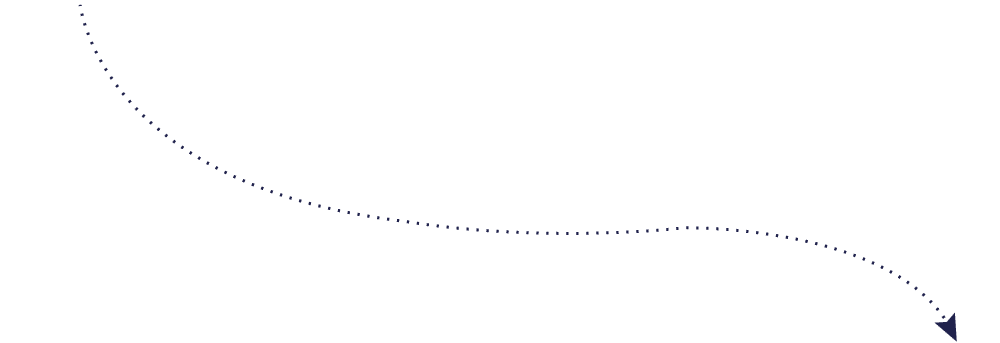

In Picomto, you create skills and define the conditions to develop your teams. Picomto manages Iluo or 4 levels (beginner, intermediate, confirmed and expert). You know at any time or are the members of your teams and you prepare the necessary developments. PICOMTO offers a complete system for managing versatility and polycompetry.

Each level corresponds to a clear vision of what the oporer can achieve. At level 1 the employee applies the operating mode and worked in safety. At level 2 the employee person applies the operating mode and makes the expected quality. At level 3 the employee knows the operating mode, makes the expected quality and quantity. At level 4 the employee is an expert. He knows the operating mode, makes the expected quality and quantity and is able to train other people.

For each level the process can be fully automatic or with validation of the team leader. Each team leader has a complete vision of the skills level of his teams and can validate or launch additional training.

You no longer have to manage two systems in parallel. Replace the training modules that cost you to maintain and create with your factory work instructions. Your operators are formed from the first day from the documents they will use in the factory.

With Picomto, you create the training courses in a few minutes. You define the conditions to be fulfilled to switch from one level to another and Picomto automatically checks the right damage to each of the steps. For example you can define how many times the operator must carry out a task containing the work instruction and/or how long he must spend this task. Thanks to the work simultaneously, Picomto am each of the steps and allows you to make sure that the operators have gone through each of them.

Picomto provides the manager of visual dashboards for managing his team’s skills and versatility. He knows at a glance or are each member of the team. The team leader can therefore act on the differences and ensure that he has the necessary and sufficiently competent resources for the execution of the tasks to come.

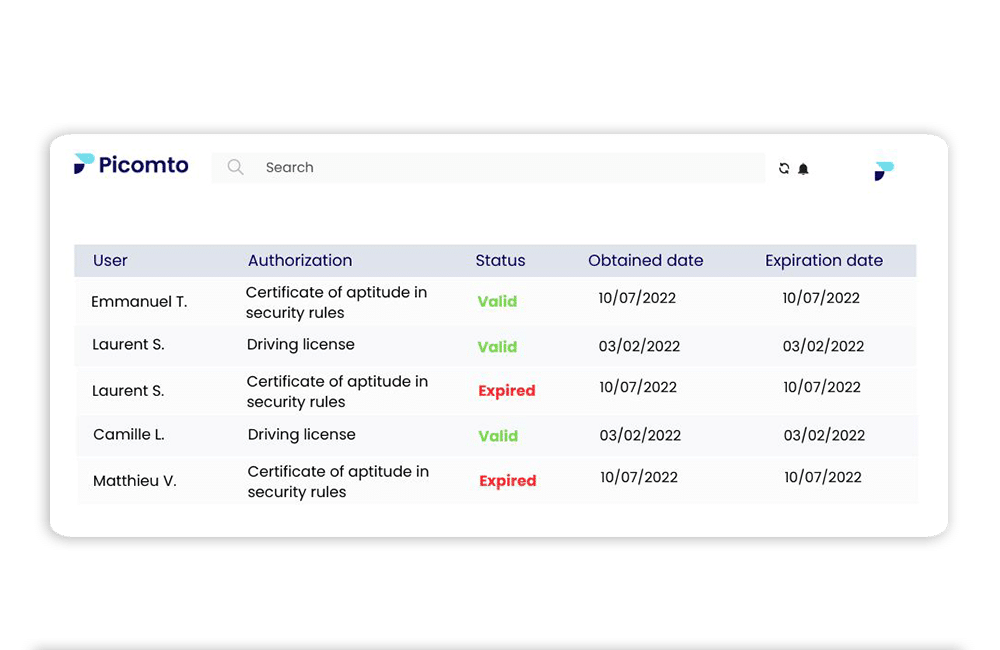

Management of work permits and authorizations

Picomto manages authorization and work permits and connects them to skills. Each skill may require one or more authorizations or a specific work permit.

Picomto provides companies with a complete calendar and recovery system. When an authorization or a license matters, the employee and the team leader are automatically relaunched in their notification center and by email. Officials can then set up the actions necessary to prevent the authorization or the permit from being permeated.

If an authorization or a permeal permit. All the skills of an employee who contain them are automatically suspended. The employee can therefore no longer carry out the tasks requiring competence and everyone is warned. The tasks containing this skill can no longer be assigned to this operator until renewed its authorization. This secures the supervision in particular in the event of an accident which can no longer take place with non -authorized staff. As soon as he is empowered again, the operator recovers the level of competence he had previously.

Picomto provides the manager of visual skills, authorizations and work permits of his team to the service manager of visual board tables. He knows at a glance or are each member of the team and what are the skills suspended or the authorization that will fall. The team leader can therefore act on the differences and ensure that he has the necessary and sufficiently competent resources for the execution of the tasks to come and avoid assigning a task to an unauthorized person.

SKF reduces training time for new hires by 80%

SKF, a Swedish multinational, is the world leader in the field of mechanical bearings. The company has 7 production sites in France with more than 3,000 employees, leading to the problem of increasing the skills of new arrivals.

- Lots of temporary workers to train (rapid turnover)

- No suitable training course

- In-room training (welcome to the station, welcome to the sector)

- Limit companionship to actions with higher added value