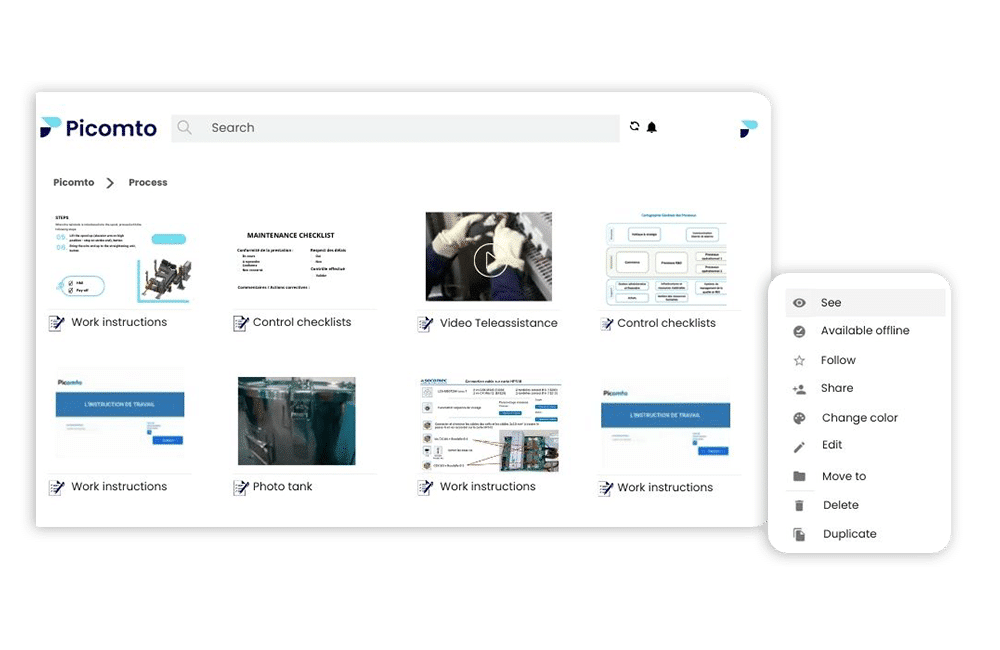

Digital instructions

Eliminate the buildup of paper documentation

Our software solution is designed to decrease paper clutter and facilitate the transition to digital processes in an AS9100 and PART21,145 compliant environment.

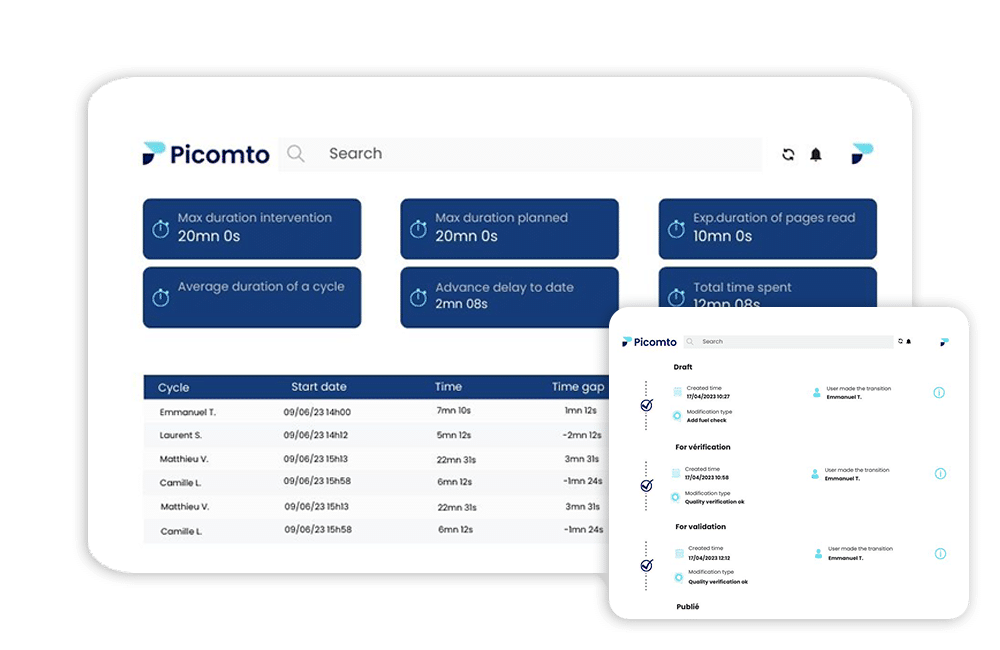

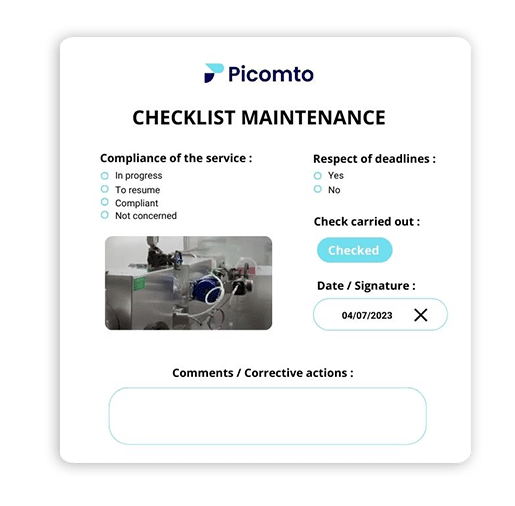

Traceability

Detect anomalies at the earliest stage

Our software solution is tailored to reduce paper-based documentation and encourage the shift toward digital processes in the aerospace industry.

“I no longer need to carry around a notebook or an informative binder, I have everything in front of me and I have a visual of everything I need. »

E. Theves

Technician, French Navy

Operations management

Adapt your instructions to manage configuration management

Picomto’s objective is to ensure digital continuity from start to finish in an environment where configuration management is essential. Our goal is to offer preparers automation for processes for modifying the instruction sheet when the configuration evolves.

Want to know more ?