Production

Answer your daily production challenges

+ 50 production lines equipped Picomto

1. You must manage your human and material resources

2. You must reduce stoppages and eradicate deviations

3. You must store the know-how of outgoing operators

The typical day in the connected factory with Picomto

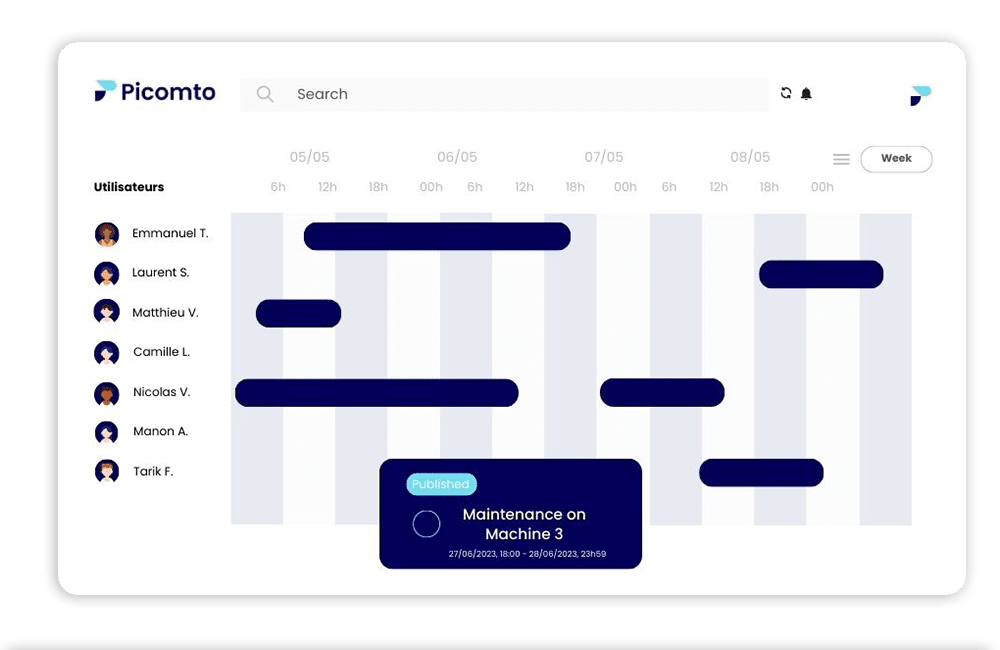

Launch of manufacturing orders

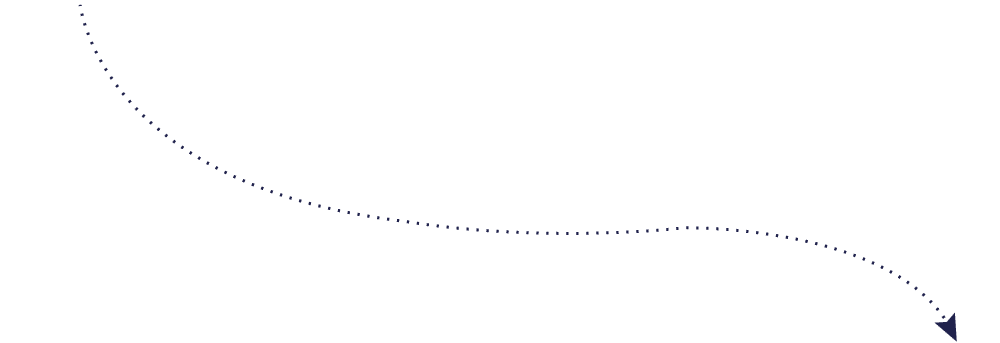

Plan your orders and affect your resources

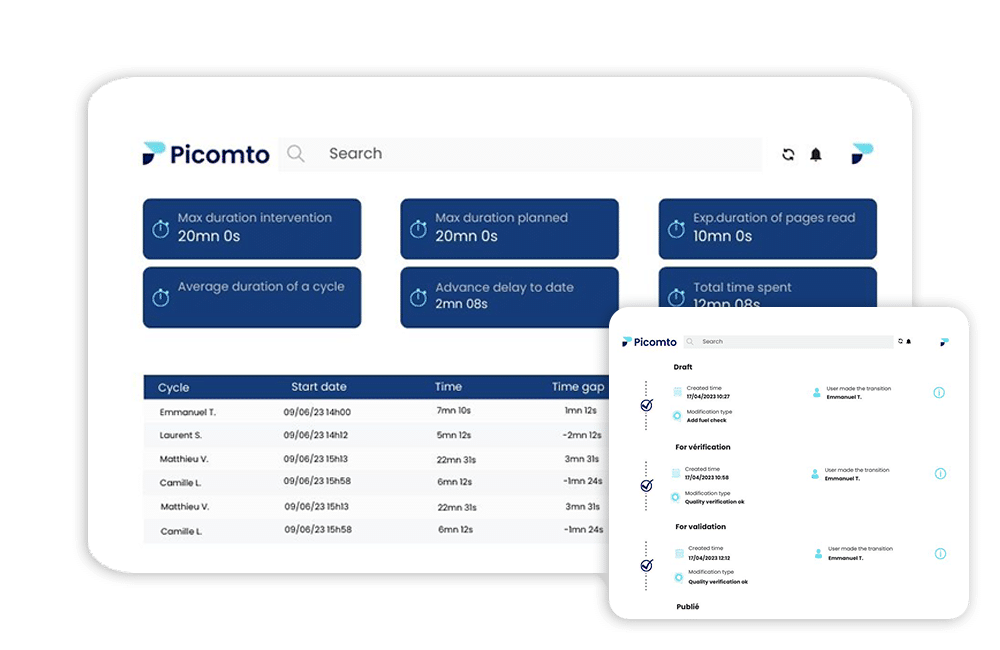

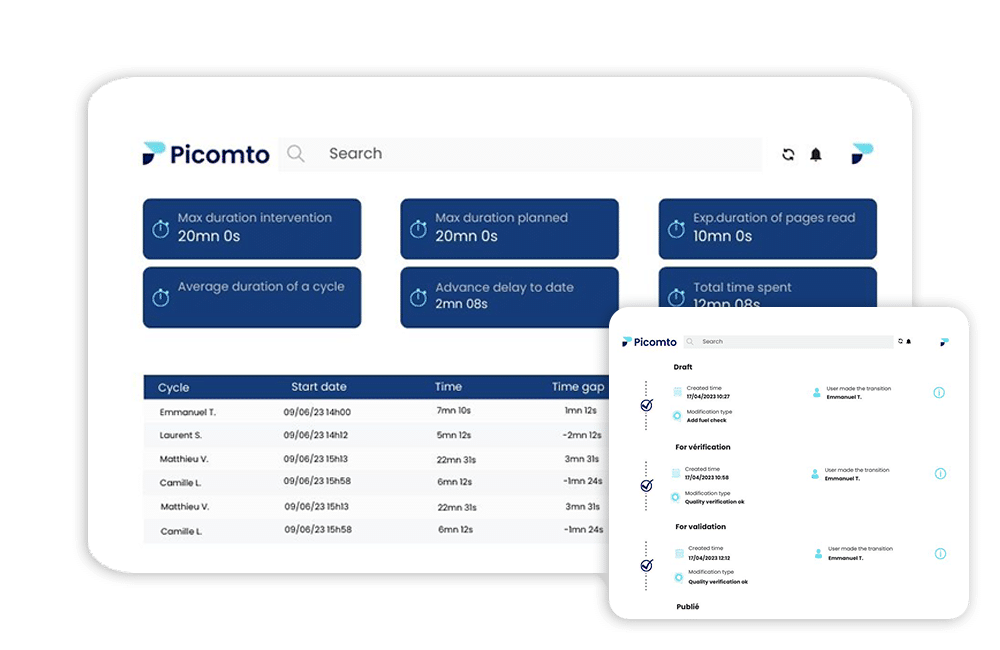

Manage the statutes of your orders, plan in advance and publish when you want.

Visualize the team load or build a dashboard adapted to your activity.

Execute your manufacturing operations

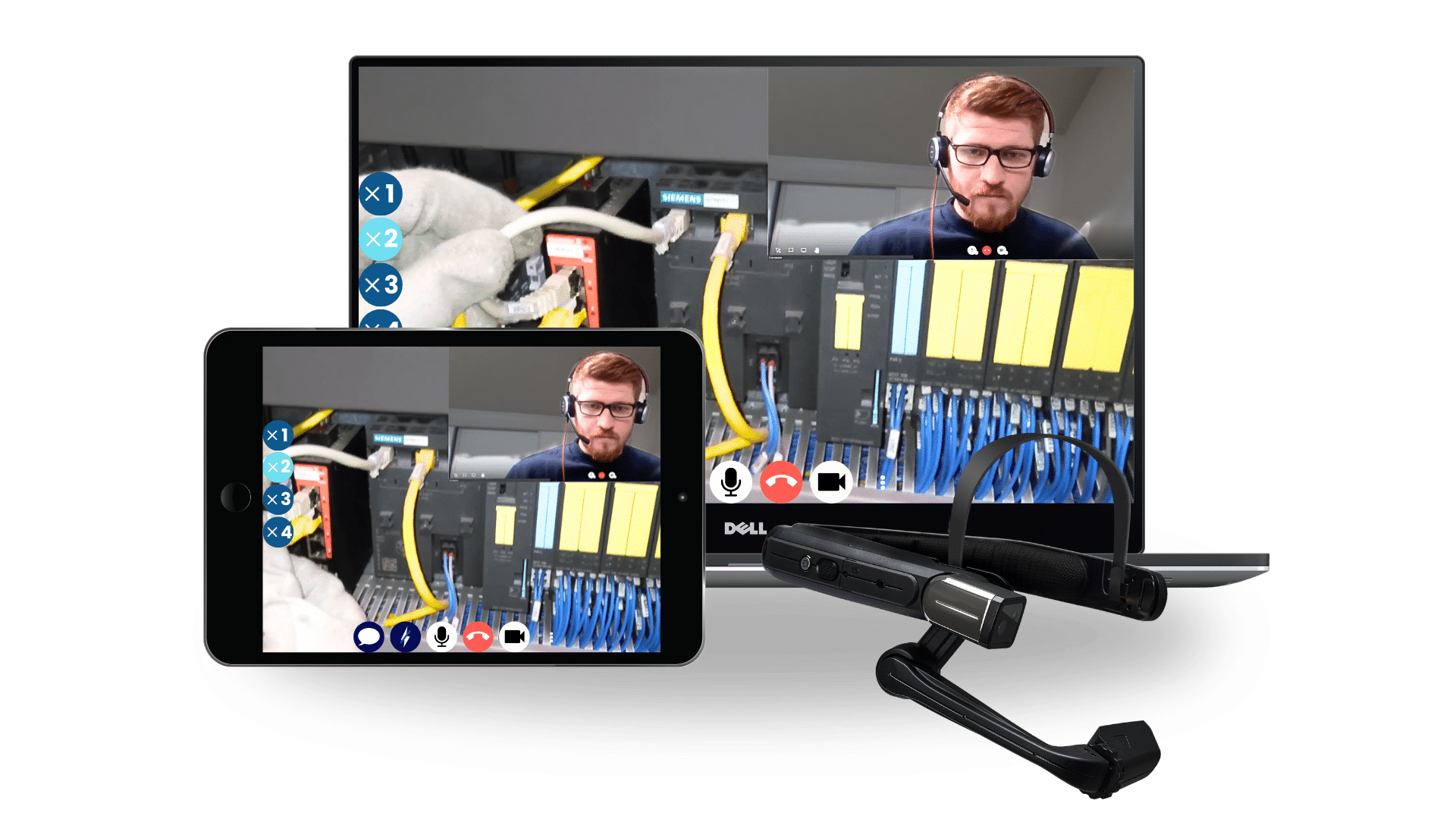

Picomto has its own remote -year and telepresence module. In closed circuit, with our own encryption keys, without access to any external service you can contact an expert or management to be assisted or validate remote operations. The implementation in Picomto makes it possible to integrate distant people into the production workflows at the crucial stages. You can film your sensitive processes or your factory without being afraid that your data flows will be intercepted or seen by your competitors.

Picomto is one of the only solutions where you can work simultaneously on the same task side by side or remotely. Your technicians and operators are synchronized in real time and everyone sees what others do. You can create intelligent workflows and condition access to the actions of some depending on the proper realization of other stages of others. Each operator sees the multimedia content captured by others and all the values entered in real time.

Follow your production and perform real-time quality checks

Make your work instructions and your smart checklists. Add validation points by supervisors or experts in workflows. Avoid closing a task before final validation. Easily set up a double control easily.

05.

Automatically close your orders and draw your inputs and exits

Digitalize your inventory forms, get out of flat files or feed your ERP directly from Picomto.

Effectively accompany your customers

Expand your offer through real -time assistance of your customers for the use and maintenance of your products. Offer an evolutionary documentary base and effective maintenance options to reduce downtime and optimize the TRS of equipment.

Find out how Butachimie digitized its production operations

Butachimie is a Seveso site located in Alsace, manufacturing basic chemicals for industry. Butachimia was looking for a reliable solution to improve its quality, production and maintenance processes by digitizing its know-how. Thus, Picomto then responded to more than 70% of the issues expressed by the site such as to increase operational efficiency or collect the data raised in real time.