New technologies, particularly those brought about by the digital boom, are benefiting all the company’s services. So much so that, for manufacturers, making the transition to digital has become as much a vector of performance as a necessary step. And if there is one area in which the plant of today and tomorrow is likely to make great progress thanks to advanced technologies, it is productivity. Technical and technological innovations are indeed real boosters for production capacities, both in terms of quantity and quality.

Digital transformation: a necessity for companies

The transition of almost all of the company’s services and activities to the era of ICT (Information and Communication Technologies), these famous information technologies, is therefore both an imperative and an opportunity for it. These innovations are expected to provide significant gains in efficiency and performance. They are designed to optimize productive capacities, exchanges, communication between all information systems and mobility. To be overtaken by this trend is to compromise your competitiveness, perhaps even your survival, because the business environment is becoming more and more competitive.

Adapting to change is a vital issue.

The company therefore complies with it and, in so doing, offers itself opportunities for improvement thanks to innovative and high-performance tools, such as cloud computing, for example. The latter is an outsourced solution that allows, among other things, huge data storage and management capacities. Technological advances also make it possible to better identify customer needs and thus improve customer satisfaction. The fact of being able to offer an adapted and personalised offer is undeniably a major asset.

The industry of the future must be able to produce more and better by implementing advanced technology systems and equipment.Productivity boosted by technological innovations

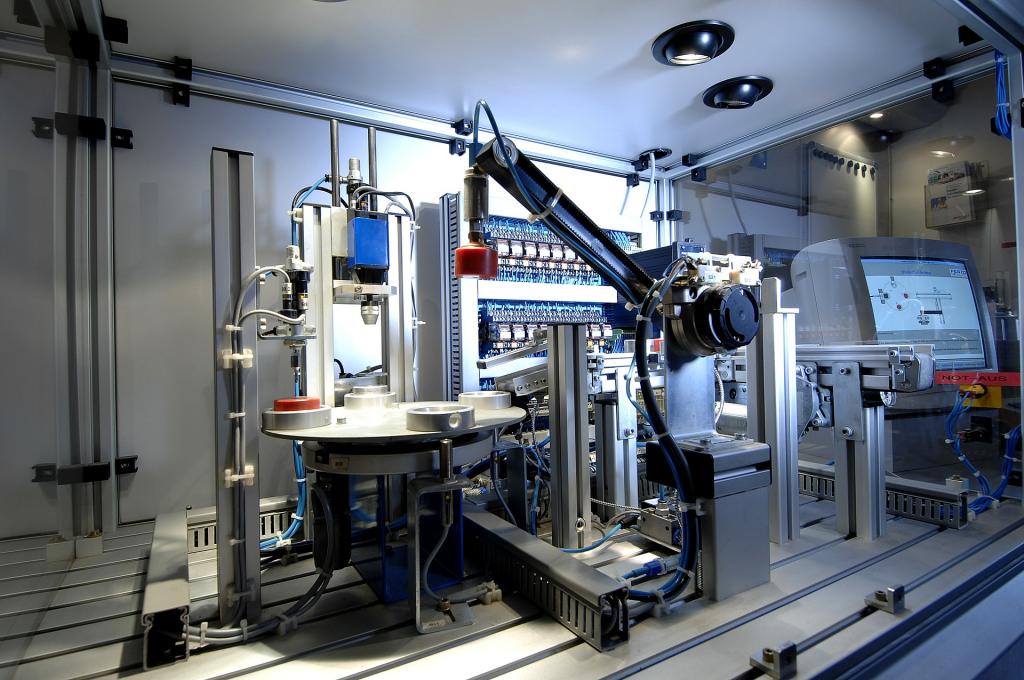

Cyber-physical systems (CPS), the pillar of industry 4.0, are a prime example of what technology can bring to productivity. In this type of device, advanced and collaboratively operating computer elements control sophisticated physical equipment (machines), increasing its reliability, efficiency and safety. These CPSs make it possible to process large quantities of data and control complex production resources, where the best of robotics and sensor networks are used, thus contributing to increasing the company’s productivity.

At the same time, new technologies are undoubtedly bringing about profound changes in the place of man in industry, which retains control over productivity and whose role is far from being devalued. Computerized and automated systems handle an ever-increasing range of repetitive and complex tasks that used to be the responsibility of the employee. This allows the latter to focus more on the management, monitoring and maintenance of this equipment, leaving the machines to do what they know best: produce in ever-increasing quantities and constantly improving quality.

Picomto is the solution to digitize your operationnal documentation. Do not hesitate to contact us to know more.

Leave A Comment