Since the work instructions precisely describe the operations to be carried out, they are decisive for the smooth running of production, as well as for maintaining and improving quality. In this respect, the work instructions have a considerable influence on the degree of competitiveness of the company, whatever its activity and size.

To fully play their role and contribute to making the company more efficient, these operating procedures must be developed with particular care. They must show the instructions precisely, unambiguously and be able to guide the employee who relies on them to accomplish his task. They must also be legible, easy to access and practical. To this end, new technologies and innovative media are favored. The industry of the future depends, in large part, on these contributions.

Work instructions, quality system and competitiveness

Work instructions are an integral part of the quality system of companies in all sectors, whether they are SMEs, ETIs or Key Accounts.

The standard operating procedures detail the instructions to be followed for each position, but also from one position to another. When these tasks are well described, work instructions provide reliable reference points for operators, who are therefore fully aware of the processes to be carried out, as well as the improper handling to be avoided. In addition, these same employees contribute to the quality of these operating procedures by providing feedback and possible suggestions to make them more efficient and to achieve faster and safer production.

Thus, if work instructions are well studied and properly applied, the products and services created are automatically more likely to comply with implicit and explicit customer expectations, ensuring their satisfaction, improving the company’s image and making it more competitive.

More accessible and practical work instructions

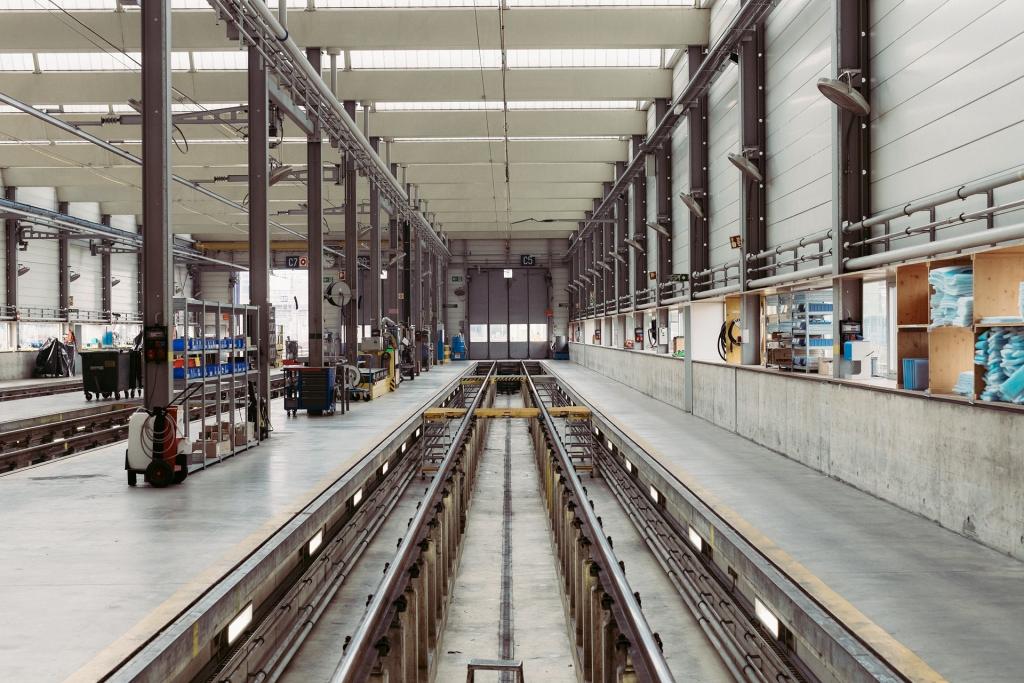

The industry is benefiting from the latest digital technological advances at all levels: communication, marketing and logistics, among others, are constantly being updated as these innovative tools are integrated, but the production chains themselves are also among the major beneficiaries of digital transformation.

Thanks to the multiplication of new media, the work instructions are presented to employees in highly explanatory and more accessible formats. In visual work instructions, alongside texts explaining the instructions to be followed, diagrams and images allow operators to have an optimized view of the processing to be carried out. But digital media go even further; digital work instructions offer much more diversified content, including videos that really explain how to proceed, offering greater proximity to the reality of the job and the tasks it involves.

While facilitating the work of employees by providing them with effective guidance, these modernized work instructions reduce the risk of error and make it easier to train new operators (replacements already in the company or new recruits).

By supporting performance at the level of the various workstations, the improved operating methods thanks to the use of recent technologies, contribute to increasing the company’s competitiveness.

About us :

Today, industry is linked to a strong problem of the transmission of knowledge. The formalization and sharing of knowledge in an industry is crucial for its present and future. Age pyramid, good practices, obligation to follow specific procedures, etc…

Picomto was born from this observation and offers the solution to capture and disseminate the industry’s know-how.

A SaaS web and mobile software solution to create, manage, share and analyze operating modes, maintenance procedures, internal procedures, after-sales support.

Picomto is part of the digitalization of the industry, #SmartIndustry #Industry4.0, #Paperless

For more information, contact us.