Key points about connected glasses for industrial maintenance:

- 45% reduction in intervention time =

- Increased precision in maintenance operations

- Accelerated technician training

- Integration with existing digital tools

- Positive ROI in less than 12 months

1. How are connected glasses transforming industrial maintenance?

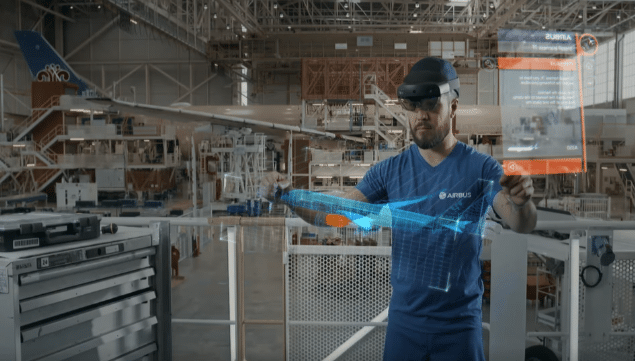

The rise of augmented reality is revolutionizing traditional maintenance practices. Thanks to connected glasses, technicians instantly access essential information without interrupting their intervention.

Result: better reactivity, increased precision, and optimization of field operations. This technology naturally integrates into industrial processes and becomes a powerful lever to improve equipment performance and reliability.

1.1. What does augmented reality bring in real situations?

In the field, every second counts. Augmented reality revolutionizes maintenance by overlaying digital instructions directly in the technicians’ field of vision.

No more need to consult manuals or waste time searching for information. At a glance, the operator visualizes the precise procedures to follow, step by step.

- Real-time guidance: the glasses display diagrams, instructions, or contextual alerts.

- Error reduction: steps are clearly indicated, limiting risks of misinterpretation.

- Time savings: interventions are more fluid and efficient.

With these tools, the quality and speed of preventive maintenance operations reach a new level of performance.

1.2 What are the concrete benefits for your teams?

The adoption of connected glasses transforms the daily life of technicians in the field. By accessing procedures and checklists instantly, they gain autonomy and efficiency.

- Uninterrupted consultation: no need to put down tools to check a paper document or tablet.

- Quick identification of intervention points: information is projected in augmented reality to precisely locate elements to check or replace.

- Securing interventions: protocols are followed to the letter thanks to interactive visual indications.

In short, technicians work faster, with increased precision and better safety.

1.3. How do they integrate into your existing processes?

The integration of connected glasses in an industrial environment happens seamlessly. They interface with your management tools and enhance the efficiency of your preventive maintenance.

- Direct connection with your CMMS: synchronization of interventions and maintenance histories.

- Real-time updates: access to the latest versions of procedures, without printing or delay.

- Interoperability with Picomto: digitized work instructions are immediately available via augmented reality display.

Thanks to this intuitive integration, your teams benefit from digital continuity that improves the reliability and efficiency of maintenance operations.

2. What are the concrete applications in maintenance?

Connected glasses revolutionize industrial maintenance by offering immediate access to essential information. Technical teams benefit from real-time digital support, thus optimizing each intervention.

This technology adapts to all industrial environments, whether production plants, complex infrastructures, or isolated sites.

2.1. How to perform a step-by-step guided intervention?

One of the main assets of connected glasses lies in their ability to display precise instructions directly in the technician’s field of vision.

No more need to consult paper manuals or navigate on a tablet: each step appears at the right time, facilitating the execution of maintenance tasks.

- Augmented reality display: procedures are projected as an overlay on the technician’s real environment.

- Interactive guidance: each step is displayed according to the progress of the intervention, ensuring error-free execution.

- Standardization of operations: technicians follow standardized instructions, improving the quality and repeatability of interventions.

2.2. How to obtain effective remote assistance?

Connected glasses offer real-time remote support, transforming the way experts assist technicians in the field.

Thanks to a live connection, specialists can see exactly what the technician is viewing and provide precise instructions using augmented reality annotations.

- Live vision sharing: the expert observes the situation in real-time and gives adapted instructions.

- AR annotations and markings: points of interest are highlighted directly on the equipment concerned.

- Reduced intervention times: technicians get immediate answers, avoiding unnecessary back-and-forth.

With this approach, resolution times decrease considerably and expert travel is reduced, generating substantial savings.

2.3. How to document your interventions in real-time?

Documentation of interventions becomes automatic with connected glasses. Instead of writing a report afterwards, the technician records each action performed in real-time.

- Automatic generation of reports: photos, videos, and voice annotations are recorded in real-time.

- Archiving and traceability: all data is stored and accessible to ensure precise monitoring.

- Integration with CMMS: reports are directly synchronized with the maintenance management system, without manual steps.

Thanks to these features, maintenance becomes more transparent, efficient, and secure.

3. What results can you expect from connected glasses?

Experience feedback confirms it: the adoption of connected glasses generates immediate and lasting benefits for industries. Maintenance teams work faster, with increased precision, while reducing operating costs.

Moreover, the return on investment (ROI) materializes in just a few months, making this technology essential for companies seeking to optimize their operations.

3.1. How much time saved on your interventions?

Time is a precious resource in industrial maintenance. Thanks to connected glasses, technicians immediately locate intervention points and instantly access the necessary instructions.

- 45% reduction in intervention time: less waiting, more efficiency in the field.

- 60% reduction in unnecessary travel: experts can guide remotely, limiting travel needs.

- Smoother operations: technicians gain autonomy and make decisions more quickly.

These improvements translate into more responsive maintenance and increased equipment availability.

3.2. How to reduce your maintenance errors?

Maintenance errors can lead to high costs and unplanned production stoppages.

With connected glasses, the reliability of interventions improves thanks to real-time visualization of procedures.

- 30% reduction in technical errors: technicians follow precise and interactive instructions.

- More effective preventive maintenance: anticipation of breakdowns thanks to detailed diagnostics.

- Automatic traceability: each intervention is documented in real-time, limiting oversights or execution errors.

By improving the precision of interventions, this technology reduces risks and optimizes equipment lifespan.

3.3. What return on investment can you hope for?

Companies that have adopted connected glasses see a quick return on investment, often in less than a year. By reducing downtime and maintenance costs, they improve their competitiveness and profitability.

- Positive ROI in less than 12 months: the investment is quickly amortized thanks to operational gains.

- Reduction in maintenance costs: reduction of corrective interventions and optimization of resources.

- Increased equipment availability (+25%): fewer breakdowns and better production continuity.

4. How to choose and deploy your connected glasses?

Choosing the right equipment is a key step to ensure the success of your project.

Each industrial environment presents specific requirements: working conditions, type of intervention, connectivity… A thorough analysis allows you to select the most suitable model and ensure smooth adoption within teams.

4.1. Which models for which types of interventions?

Not all connected glasses meet the same needs. Depending on the type of intervention and the industrial environment, certain models stand out.

- RealWear: designed for demanding environments, they are robust, shock-resistant, and adapted to field interventions.

- Microsoft HoloLens: ideal for advanced technical training and 3D visualization, they offer total immersion in mixed reality.

- Other specialized models: depending on the constraints of your sector (temperature, brightness, connectivity), there are solutions adapted to specific needs.

Depending on your priorities – step-by-step guidance, remote assistance, automatic documentation – choosing the right model ensures effective adoption and tangible performance improvement.

4.2. How to train your teams effectively?

The effectiveness of connected glasses relies on quick and intuitive handling. Appropriate training for technicians helps overcome barriers and ensures progressive adoption.

- One-day training: simplified interfaces allow for quick appropriation.

- Progressive approach: demonstrations, practical exercises, and simulations facilitate integration.

- Personalized support: sessions adapted to the specific needs of each team maximize effectiveness.

Thanks to this approach, resistance to change decreases and the tool becomes a real lever for improving maintenance interventions.

4.3. What steps for a successful integration?

The deployment of connected glasses follows a structured approach to ensure smooth and progressive adoption.

- Pilot project: test the solution on a limited scope to evaluate its effectiveness in real conditions.

- Adaptation of procedures: progressively digitize instructions and optimize workflows.

- Global deployment: once adjustments are made, the equipment is generalized to all teams.

- Monitoring and optimization: analyze feedback to refine uses and maximize benefits.

Conclusion

Connected glasses represent a strategic investment to modernize your industrial maintenance. By associating them with digital solutions like Picomto, you optimize your entire maintenance chain. From documentation to execution of interventions, each step gains in efficiency.

FAQ

Q: Do connected glasses work without an Internet connection?

A: Some features remain available in offline mode with later synchronization.

Q: What training should be planned for technicians?

A: One day is generally sufficient to master the essential functionalities.

Q: Are connected glasses resistant to difficult industrial environments?

A: Yes, industrial models resist dust, shocks, and extreme temperatures.

Q: Can connected glasses be used to train new technicians?

A: Absolutely, they accelerate learning in real situations by 40%.

Leave A Comment