Maintenance is one of the vital components of the industry. It has continuously improved as production processes and equipment have evolved, and it is therefore in the natural order of things that it continues to do so in the future. For the industry of the future, the objective is to reduce downtime to its simplest expression, to move towards “zero downtime”. This is not an unattainable goal, since technological progress in the service of maintenance is considerable, provided in particular that data are used wisely and maintenance is organized in the best possible way.

Better data collection and analysis

Data is the key to maintenance. It is the information collected from the machine that provides information about its condition and performance, indicating whether or not it is time for a troubleshooting, repair or change. The quality of data collection and interpretation is therefore essential to a company’s maintenance policy.

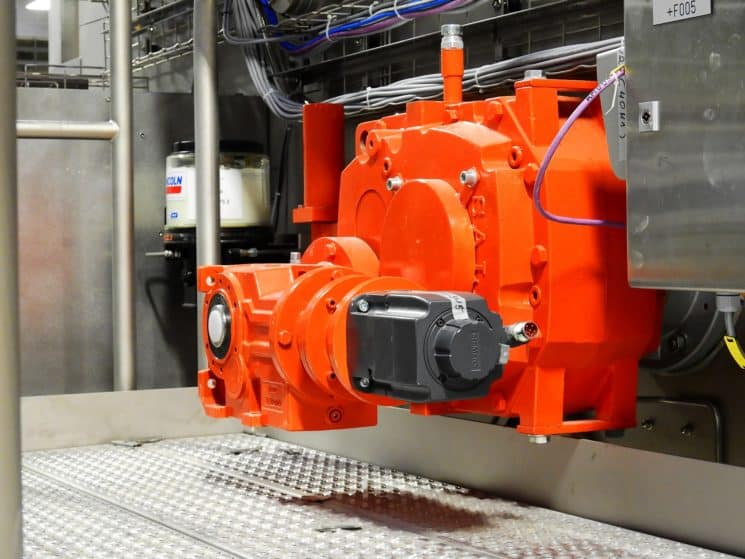

In this area, continuous improvements are being made to ensure that the industry of the future can truly reduce downtime. Maintenance benefits from the integration of cutting-edge technologies, such as intelligent sensors, virtual reality, laser remote sensing for 3D surveys of hard-to-reach equipment, UV sensors, infrared sensors and drones. These innovations are combined with advances in information storage, transfer and processing capacity to create systems that are more reliable and efficient.

While the latter provide a definite advantage in terms of corrective maintenance, most of them are more oriented towards improving predictive maintenance. These systems are designed to help companies to avoid failures leading to stoppages and to anticipate them through efficient interpretation of the information recorded by the sensors. These alert technicians when vibrations, mechanical play, fluid quality (oils) or temperature levels are approaching critical thresholds, beyond which the machine may fail. This means that interventions can be planned and scheduled well in advance and not be caught off guard.

Reduce downtime and costs

Reducing downtime is the goal of every industrial company, because downtime significantly penalizes productivity and generates costs. In addition, they affect the company’s image with its customers through late deliveries and lower quality.

The costs of maintaining and managing existing assets can become extremely high and increasingly difficult to meet without a flawless organization. Machines that are not properly monitored and maintained are irreparably shortened in life, making it necessary to spend a lot of money to replace them.

The challenge of maintenance is therefore also of a financial nature for the industry of the future, which must control its costs and optimize all its resources in order to remain competitive.

About Picomto

Picomto is the web and mobile software solution for creating, managing, sharing, consulting and analyzing visual work instructions.

Leave A Comment