Do your industrial machines represent a financial drain rather than a profitable investment? Does industrial machine durability truly transform your company's performance? These crucial questions concern all production managers today. Indeed, industrial machine durability constitutes a major strategic challenge that directly determines the competitiveness and sustainability of manufacturing companies. In a demanding economic context and facing growing environmental challenges, optimizing the longevity of your equipment becomes imperative. This approach significantly reduces maintenance costs, minimizes unplanned production downtime, and limits the environmental impact of your industrial activity.

Key takeaways regarding the improvement of industrial machine durability:

- Cost reduction: Better durability decreases maintenance expenses by 20 to 40%

- Availability optimization: Durable machines increase productivity by up to 25%

- Environmental impact: Equipment longevity reduces industrial carbon footprint

- Improved ROI: Investments in durability generate significant return on investment

- Process digitalization: Digital work instructions optimize maintenance interventions

1. Why is industrial machine durability so important?

Industrial machine durability has become a crucial competitiveness factor for companies.

Facing a constantly evolving industrial environment, adopting a sustainable approach directly influences operational performance, environmental impact, and overall profitability. Understanding its multiple facets is essential to grasp the current challenges of the manufacturing sector.

1.1. What are the economic advantages of better durability?

The economic benefits of optimized durability quickly translate into tangible financial results. Here are the main advantages:

- Maintenance cost reduction: Significant decrease in corrective expenses, often between 20% and 40%.

- Increased machine availability: Drastic reduction in unplanned downtime, thus optimizing production rates.

- Improved residual value: Well-maintained machines retain superior market value during resale or replacement.

1.2. How does increased durability impact the environment?

The environmental impact of industrial machine durability is substantial:

- Reduced resource requirements: Extending equipment lifespan significantly reduces the need for manufacturing new machines.

- Decreased energy consumption: Well-maintained machines operate more efficiently, consuming less energy for the same production output.

- Reduced industrial waste: Fewer failing components result in less metallic waste and electronic components to process.

1.3. How does durability improve workplace safety?

A sustainable approach to industrial machine maintenance directly improves workplace safety:

- Reduced failure risks: Properly maintained equipment presents fewer risks of sudden failure and accidents.

- Failure predictability: Anticipation of dangerous interventions, allowing operators to work in a safer environment.

- Reinforced safety culture: Continuous team training on maintenance best practices fosters a strengthened safety culture.

2. What are the main factors that influence industrial machine durability?

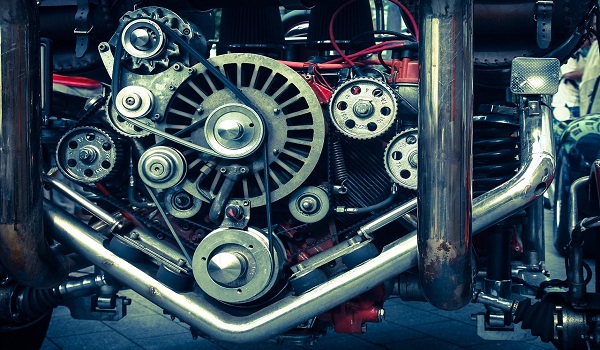

Industrial machine durability is a crucial issue that directly impacts their performance and longevity. It relies on a complex interaction of several interconnected factors.

A holistic approach, considering all these elements, is essential to optimize equipment lifespan. Identifying and mastering these parameters is the foundation of an effective durability strategy.

2.1. What role does material quality play?

Material quality is a fundamental pillar of industrial machine durability.

- Enhanced resistance: High-performance materials are more resistant to mechanical and thermal stresses, significantly extending component lifespan.

- Protection against corrosion and wear: Specialized surface treatments protect against corrosion and premature wear, preserving the initial properties of components.

- Customized solutions: Innovation in metallic alloys offers solutions adapted to the specific requirements of each industrial application.

2.2. How does maintenance impact durability?

Maintenance is a direct action lever for optimizing industrial machine durability.

- Preventive maintenance: Rigorous preventive maintenance planning allows anticipating failures and avoiding them.

- Intervention quality: Standardized procedures and quality execution guarantee the effectiveness of corrective actions.

- Technician training: Adequate technician training ensures mastery of maintenance techniques specific to each equipment.

2.3. What is the influence of the operational environment?

The operating environment has a significant influence on industrial machine durability.

- Ambient temperature: Ambient temperature affects the performance of electronic and mechanical components.

- Humidity and contaminants: Humidity and atmospheric contaminants accelerate material corrosion and oxidation.

- Vibrations and shocks: Vibrations and mechanical shocks can prematurely damage sensitive elements.

2.4. How does machine usage affect their durability?

The way machines are used directly influences their durability.

- Capacity compliance: Respecting the machine’s rated capacities preserves its structural integrity.

- Cycle regularity: Regular usage cycles are beneficial for the longevity of mechanical components.

- Operator competence: Operators’ daily practices have a significant impact on equipment lifespan

3. What are effective strategies for improving industrial machine durability?

Industrial machine durability relies on a combination of proven and innovative strategies.

These approaches, integrating cutting-edge technologies, operational best practices, and digital tools, aim to maximize equipment performance and longevity. Their effectiveness lies in their adaptation to each industrial environment’s specificities and their harmonious integration into existing processes.

3.1. How can predictive maintenance extend machine life?

Predictive maintenance represents a major advancement in improving industrial machine durability. It is structured around several pillars:

- Real-time data collection: IoT sensors collect crucial data on equipment condition, enabling identification of weak failure signals.

- Predictive analysis with AI: Artificial intelligence analyzes trends and accurately predicts maintenance needs, thus avoiding costly breakdowns.

- Intervention schedule optimization: Maintenance is planned proactively, reducing downtime while ensuring optimal operational efficiency.

3.2. How does digitalization of work instructions with Picomto improve durability?

Digitalization of work instructions with Picomto radically transforms industrial machine durability:

- Consistency and precision: Digital procedures guarantee consistency and precision in maintenance interventions.

- Complete traceability: Recording all actions enables practice optimization and improvement identification.

- Instant access to information: Quick access to technical information reduces human errors and accelerates corrective interventions.

4. How to implement an effective durability strategy for your industrial machines?

Implementing a durability strategy for your industrial machines requires a methodical and structured approach. This process involves several crucial steps, from initial assessment to performance monitoring.

It is therefore essential to understand each phase of the process to maximize your investment efficiency and guarantee sustainable improvement of your equipment.

4.1. Where to start with assessing your machines' current condition?

Current condition assessment constitutes the first fundamental step of your strategy. It is crucial to:

- Conduct a comprehensive audit of your existing equipment.

- Precisely document the age, maintenance history, and performance of each machine.

- Collect production data, downtime, and maintenance costs to identify the most critical equipment.

- Analyze recurring failure modes to understand weak points.

- Involve your field teams: their daily observations provide valuable insights into actual machine behavior. Complement this information with objective measurements and technical inspections.

4.2. How to define realistic durability objectives?

Defining realistic objectives relies on your initial assessment results. These objectives must be:

- Specific: clearly defined.

- Measurable: quantifiable to track progress.

- Achievable: realistic given available resources.

- Defined within a precise timeframe.

For example, aim for a 15% reduction in unplanned failures over 12 months. Align your objectives with your company's overall strategy to guarantee consistency between durability investments and business results.

Prioritize the most critical machines for your production.

Establish progressive milestones rather than a single long-term objective to facilitate monitoring and maintain team motivation.

Remain ambitious while being pragmatic about available resources.

4.3. What technologies and strategies to choose for your company?

Technology choice depends on your specific objectives and budget. Consider:

- IoT-based predictive maintenance solutions: to continuously monitor your machines' condition.

- Maintenance procedure digitalization tools: to standardize interventions and reduce human errors.

- Computerized Maintenance Management System (CMMS) platforms: to centralize all information.

- Smart sensors: to collect real-time data and detect anomalies before they cause failures.

However, ensure your teams master these new technologies.

4.4. How to train your teams and implement new procedures?

Team training is a key success factor for improving industrial machine durability. It is important to:

- Identify necessary skills for each position.

- Develop a training program adapted to specific needs.

- Organize theoretical and practical sessions to guarantee complete assimilation.

- Use digital tools to create interactive work instructions.

- Involve your teams in developing new procedures.

- Standardize practices to ensure consistent intervention quality.

- Implement an internal certification system to validate acquired skills.

- Provide regular update training.

4.5. What indicators to monitor to measure durability improvement?

Monitoring relevant indicators allows evaluating your durability strategy's effectiveness. It is necessary to:

- Measure the Overall Equipment Effectiveness (OEE) of your equipment.

- Monitor the number of unplanned failures and their average duration.

- Analyze maintenance cost evolution relative to revenue.

- Track Mean Time Between Failures (MTBF) for each critical equipment.

- Measure Mean Time To Repair (MTTR) to optimize interventions.

- Integrate environmental indicators such as specific energy consumption.

However, regularly update your alert thresholds.

Conclusion

Improving industrial machine durability requires a comprehensive and methodical approach. Key points include rigorous existing condition assessment, realistic objective definition, and appropriate technology adoption. Additionally, team training and relevant indicator monitoring guarantee your approach's success.

Acting now to improve your industrial machine durability represents a strategic investment. Picomto accompanies you in this digital transformation through its innovative procedure digitalization solutions. Our tools enable maintenance optimization, effective team training, and precise performance indicator monitoring.

Request a personalized demonstration to discover how Picomto can transform your industrial operations.

FAQ

How can industrial productivity be improved?

Optimize preventive maintenance, train teams, and digitalize industrial procedures.

How can I improve my machine availability?

Monitor key indicators, plan maintenance, and reduce downtime.

Why do manufacturers need to maintain their machines?

Maintenance preserves performance, reduces costs, and guarantees safety.

How can I improve my equipment maintainability?

Standardize procedures, train technicians, and use digital tools.

How can productivity and efficiency be improved?

Measure performance, eliminate waste, and optimize industrial processes.

What factors influence productivity?

Maintenance, training, technology, and work organization directly impact productivity.

Leave A Comment