Imagine being able to monitor, diagnose, and repair your industrial equipment from anywhere in the world, 24/7. Remote control of industrial equipment transforms this vision into reality. This revolutionary technology enables companies to manage their assets in real-time, optimize their maintenance operations, and significantly reduce their operational costs. Within the Industry 4.0 ecosystem, remote control becomes an indispensable competitive advantage for companies seeking to maintain their market leadership.

Key takeaways regarding remote control of industrial equipment:

- Enhanced efficiency: 40% reduction in intervention time through real-time monitoring

- Substantial savings: Maintenance cost reduction of up to 30%

- Reinforced safety: Remote intervention limiting exposure to risks

- IoT connectivity: Seamless integration with existing systems

- Cybersecurity: Protection of critical data and infrastructure

Ready to explore the infinite possibilities of remote control?

Contact our experts for a personalized consultation!

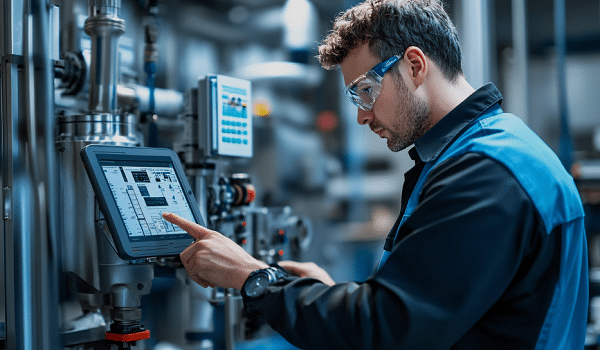

1. What is Remote Control of Industrial Equipment?

Remote control of industrial equipment represents a revolutionary approach to industrial asset management. This technology enables operators to monitor, diagnose, and control their equipment without being physically present on-site.

Through connected sensors and intelligent platforms, companies can now manage their operations from any location, thus ensuring optimal service continuity.

1.1. How does Remote Control Work in Industry?

The operation of remote control relies on several key components:

- IoT sensors collecting real-time data

- Cloud platforms centralizing information

- User interfaces enabling remote interaction

- Artificial intelligence algorithms analyzing data

These elements orchestrate to create an intelligent and responsive ecosystem.

1.2. What Types of Equipment Can Be Remotely Controlled?

The diversity of equipment compatible with remote control is impressive:

- Production systems: assembly lines, industrial robots

- Maintenance equipment: pumps, compressors, motors

- Security systems: alarms, cameras, detectors

- Energy infrastructure: transformers, generators

1.3. How Does Remote Control Differ from Traditional Methods?

The fundamental difference lies in the proactive versus reactive approach:

- Continuous monitoring instead of periodic inspections

- Immediate response rather than delayed corrections

- Predictive maintenance replacing corrective maintenance

- Real-time optimization versus manual adjustments

2. What are the Main Advantages of Remote Control for Industry?

The advantages of remote control of industrial equipment radically transform industrial performance.

Companies adopting this technology observe significant improvements in all aspects of their operations. From cost reduction to safety improvement, remote control offers remarkable and sustainable return on investment.

2.1. How Does Remote Control Improve Operational Efficiency?

Operational efficiency directly benefits from remote control:

- Average 50% reduction in downtime

- Automatic optimization of production parameters

- Rapid anomaly diagnosis

- Centralized coordination of interventions

This approach enables achieving unparalleled performance levels.

2.2. What Savings Can Be Achieved Through Remote Control?

The savings generated by remote control are substantial:

- Maintenance costs: 25-30% reduction

- Travel expenses: 60% decrease

- Intervention time: 40% optimization

- Energy consumption: 15% savings

These figures demonstrate immediate positive financial impact.

2.3. How Does Remote Control Enhance Operator Safety?

Safety constitutes a major advantage of remote control:

- Reduced exposure to hazardous environments

- Permanent monitoring of working conditions

- Automatic alerts in critical situations

- Secure interventions through remote maintenance

3. What Technologies Enable Remote Control of Industrial Equipment?

The technologies enabling remote control of industrial equipment are rapidly evolving. The Internet of Things, augmented reality, and artificial intelligence converge to create increasingly sophisticated solutions.

These innovations allow companies to push the boundaries of what was previously considered impossible in remote management.

3.1. What Role Does the Internet of Things (IoT) Play in Remote Control?

IoT constitutes the foundation of modern remote control:

- Intelligent sensors collecting precise data

- Permanent connectivity between equipment and systems

- Real-time processing of critical information

- Seamless integration with existing infrastructure

This technology transforms every piece of equipment into a source of intelligence.

3.2. How Does Augmented Reality Facilitate Remote Maintenance?

Augmented reality revolutionizes industrial maintenance:

- Visual guides superimposed on real equipment

- Contextual instructions adapted to each situation

- Shared expertise between remote and local technicians

- Immersive training for new operators

This technology democratizes advanced technical expertise.

3.3. Why is Cybersecurity Crucial for Remote Control?

Cybersecurity protects critical industrial assets:

- Data encryption in transit and at rest

- Multi-factor authentication for access

- Continuous monitoring of intrusion attempts

- Regular security system updates

Without robust cybersecurity, remote control exposes companies to major risks.

4. How Does Picomto Revolutionize Remote Control of Industrial Equipment?

Picomto transforms remote control of industrial equipment through its innovative platform. This comprehensive solution integrates all necessary functionalities for efficient industrial asset management.

By combining ease of use with technological power, Picomto enables companies of all sizes to benefit from remote control advantages.

4.1. What Unique Features Does Picomto Offer for Remote Control?

Picomto offers revolutionary functionalities:

- Intuitive interface accessible from any device

- Customizable intelligent notifications

- Detailed intervention history

- Native ERP integration with existing systems

These characteristics distinguish Picomto from its competitors.

4.2. How Does Picomto Ensure Accurate Real-Time Information Dissemination?

Information accuracy constitutes Picomto’s DNA:

- Instant synchronization between all users

- Automatic validation of critical data

- Version control for procedures

- Complete traceability of modifications

This approach guarantees shared information reliability.

5. How Does “Picomto Remote Expert” Solution Transform Remote Maintenance?

Remote Expert redefines industrial remote maintenance:

- Real-time assistance through high-definition video

- Direct annotation on live image

- Screen sharing for complex diagnostics

- Automatic intervention recording

This solution enables “teleporting” expertise where needed.

6. How to Successfully Implement Remote Control in Your Company?

Successful implementation of remote control of industrial equipment requires a methodical approach.

Each company must adapt this technology to its organizational and technical specificities. Planning, training, and monitoring constitute the pillars of successful transition to remote control.

6.1. What Steps to Follow for Successful Transition to Remote Control?

A structured methodology guarantees success:

- Initial audit of existing equipment and processes

- Definition of objectives and performance indicators

- Pilot on restricted perimeter before global deployment

- Team training and change management

This progressive approach minimizes risks and maximizes adoption.

6.2. How to Choose the Remote Control Solution Adapted to Your Needs?

Solution choice determines project success:

- Evaluation of functional and technical requirements

- Comparison of available market solutions

- Real-condition testing with user teams

- Long-term cost-benefit analysis

This approach ensures judicious and sustainable investment.

6.3. What Return on Investment Can Be Expected from Remote Control?

Remote control ROI is measured across several dimensions:

- Productivity gains

- Cost reduction

- Quality improvement

- Customer satisfaction

These results largely justify the initial investment.

Conclusion

Remote control of industrial equipment, supported by innovative solutions like Picomto, redefines modern industry.

By offering more efficient management, proactive maintenance, and increased flexibility, it enables companies to remain competitive in a constantly evolving market. Adopting these technologies is no longer an option, but a necessity for those aiming for operational excellence and continuous innovation.

Ready to transform your industrial equipment remote control? Request a free demo today and take the first step toward the industry of the future!

FAQ :

What is the best remote control software?

Picomto leads the market with its advanced features and intuitive interface.

How to take remote control?

Use IoT sensors connected to a secure cloud platform like Picomto.

How to control remote work?

Monitor real-time indicators and use interactive digital instructions.

Leave A Comment